Oleoresin

Oleoresin refers to a highly concentrated, mostly viscous extract from spices or herbs. It contains both the volatile aroma components and the non-volatile, flavour-giving ingredients of the source material. Oleoresins thus combine essential oils and resinous components in a homogeneous phase.

In spice refinement, oleoresins are obtained from raw spices such as pepper, chilli, paprika, nutmeg, ginger or herbs. They are usually produced by extraction with organic solvents. Hexane, ethanol or supercritical carbon dioxide are often used. After extraction, the solvent is largely removed.

Oleoresins are often dispersed in vegetable oils for stabilisation and protection against oxidation. Alternatively, there are also water-based spice extracts, but these have a different composition and lower lipophilicity.

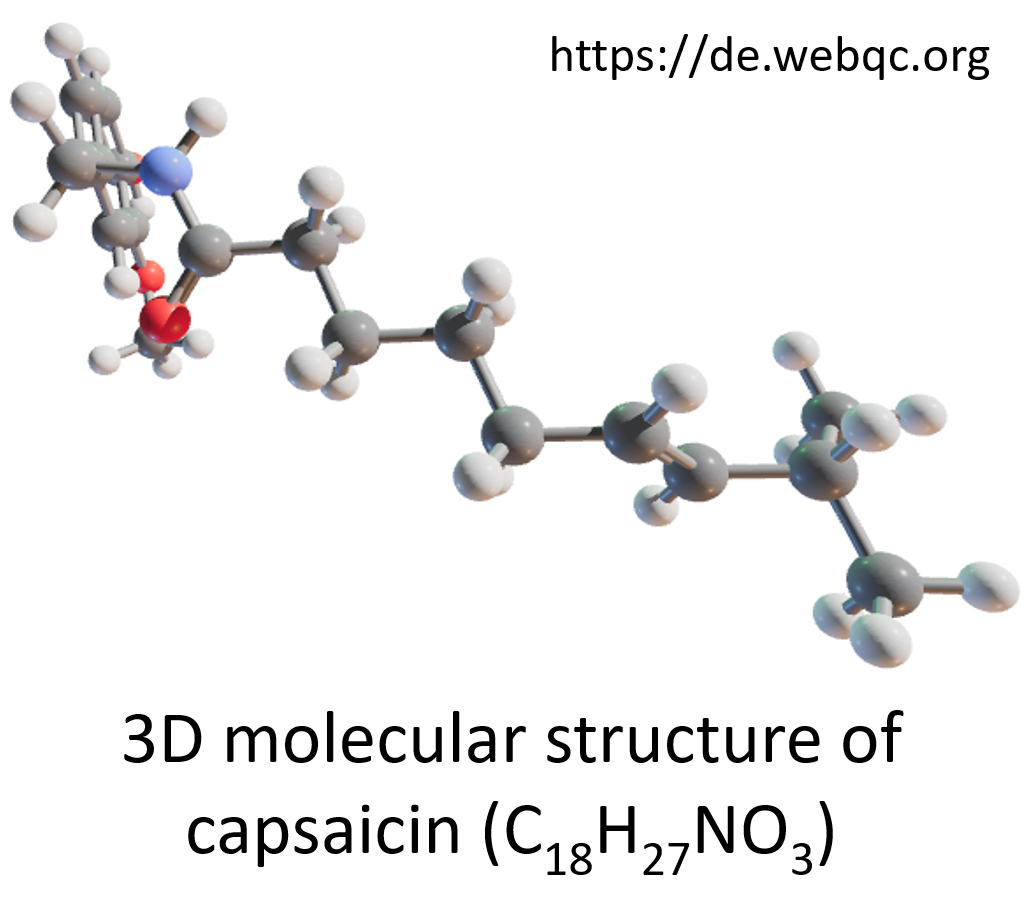

Chemically, oleoresins consist of complex mixtures of substances. They contain terpenes, alkaloids, phenols, resins and fatty acids. A well-known example is capsaicin from chilli peppers. Its molecular formula is

C₁₈ H₂₇ NO₃

Capsaicin is highly lipophilic and practically insoluble in water, but highly soluble in oils. This property explains the typical oil binding of chilli and paprika oleoresins.

Oleoresins are usually extremely highly concentrated. Even very small amounts are sufficient to achieve intense sensory effects. Pepper and chilli oleoresins have a strong irritant effect on the skin and mucous membranes. They are therefore also used in defence sprays. Contact can cause considerable irritation, chemical burns and inflammation of the skin and eyes. Handling oleoresins therefore requires special care, appropriate protective measures and closed process control.

Oleoresins also pose a challenge from a process engineering perspective. They are chemically very active and can attack many elastomers and polymer seals. Only polytetrafluoroethylene is generally resistant in the long term. In addition, many oleoresins have an extremely intense odour. Even small leaks can cause lasting contamination in production areas.

Due to their high concentration, oleoresins are only used in very small doses in powdered food mixtures. This places high demands on the wetting and mixing process. The aim is to achieve an even distribution that is proportionate to the content on as many powder particles as possible. Local overdoses must be avoided as they can lead to clumping, agglomeration and sensory inhomogeneities.

The wetting process must be fast and efficient. There must be no significant heating of the powder. Many oleoresins are sensitive to temperature and oxidation. amixon® mixers have proven particularly effective for these and other types of spice processing. They achieve ideal mixing qualities with short mixing times. They operate at low tool speeds. This minimises dust formation, heating and agglomeration. amixon® mixers have high self-cleaning effects and can empty themselves almost completely.