multi-step mixing method

Complex instant food mixtures contain components with very different properties. Some powders absorb liquid well without clumping. Others tolerate high shear energy and can be reliably wetted even with viscous liquids. Fine dust particles can easily coat over-moistened particles and bind free moisture. This removes dust from the product and improves its flowability. The targeted use of these raw material properties is an essential part of the multi-step strategy.

In the past, several premixes were produced in small powder mixers. These premix batches were then transferred to a large or final mixer, where they were combined to form the finished product. This procedure required the use of several mixing machines and frequent transfer.

amixon® cone mixers can often simplify this process. The premixes are added step by step until the final mixture is achieved – all in the same mixer.

First, the robust components are charged and wetted with the highly viscous liquids. These are usually intensive mixing processes. The main mixing tool and the cutting rotors rotate at high speed. The mixing tools are then stopped. Now further powder components are added. The mixing process then starts at adjusted speeds while further liquids are sprayed on. This gradually increases the fill level in the mixer. This process is repeated until all powder and liquid components are in the mixer. Very fragile ingredients such as pieces of vegetables, fruit, croutons, meat preparations, dumplings, or potato pieces are only added at the end. They are “folded in” very gently. This preserves their structure.

An amixon® cone mixer allows both premixing and final mixing to be carried out in the same apparatus. This is possible because this type of mixer achieves the full performance of cutting rotors, knife heads, and deagglomerators even at very low filling levels. The tools can be placed deep in the cone and work efficiently even with minimal product quantities.

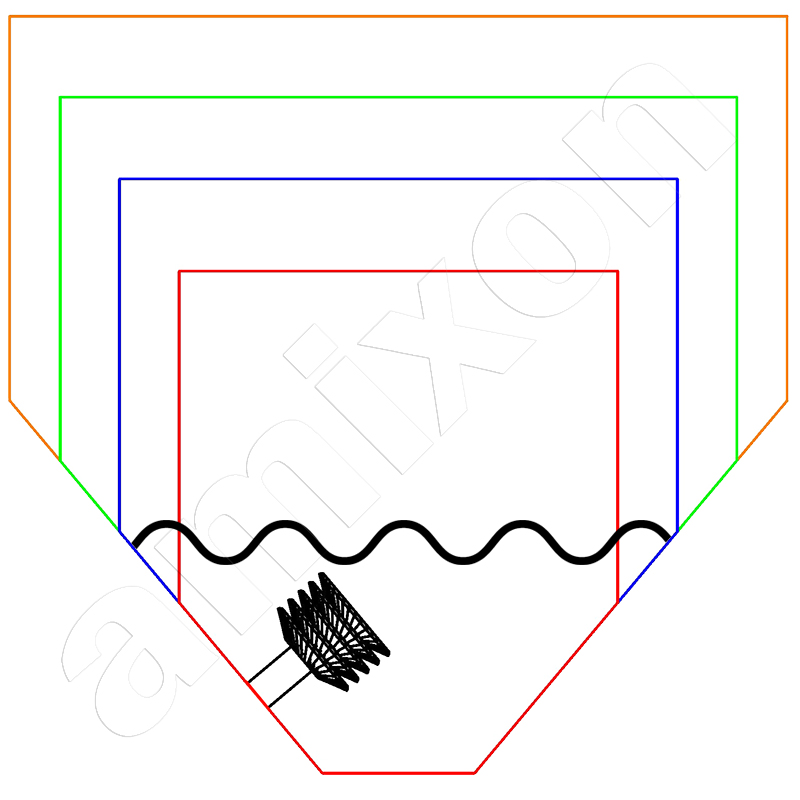

The image on the left shows amixon® cone mixers of various sizes with a congruent design. The black wavy line indicates the minimum fill level. The cutting rotor is located in the same position for all sizes. This means that even very large cone mixers can be operated with extremely low fill levels.