Large fermenter: Gyraton® silo mixer becomes a fermenter/reactor

The Gyraton® mixing technology from amixon® is an innovation in the field of large-scale material processing. It uniquely combines two contrasting requirements: “absolute product protection with excellent mixing quality.” The Gyraton® mixing process meets the highest hygiene standards – even with batch sizes of up to 100 m³.

Fermentation is a particularly elegant form of material conversion. Unlike chemical synthesis, biotechnological processes take place at moderate temperatures, do not require aggressive solvents, and generally produce fewer environmentally harmful by-products. The conversion is carried out by enzymes or microorganisms—slowly but sustainably.

The trend in the pharmaceutical, biomedical, and food processing industries is clearly moving toward biological processes whenever technically and economically feasible. Even though fermentation takes significantly more time, it is preferred due to its efficiency, selectivity, and environmental compatibility. Nevertheless, both approaches—chemical and biotechnological—will remain relevant in the future.

Fermentation processes usually take place in an aqueous phase. However, the rheological properties of such systems can change significantly: from thin-liquid Newtonian to highly viscous dilatant or even pasty. Such changes have a negative effect on oxygen distribution, substrate homogeneity, and temperature control in the reactor.

Continuous stirring is therefore essential to stabilize fermentation processes and achieve reproducible results. The challenge: The stirring system must not generate shear forces or local pressure stress, but must still homogenize all areas of the reactor throughout.

The Gyraton® silo mixer as a biotechnological reactor

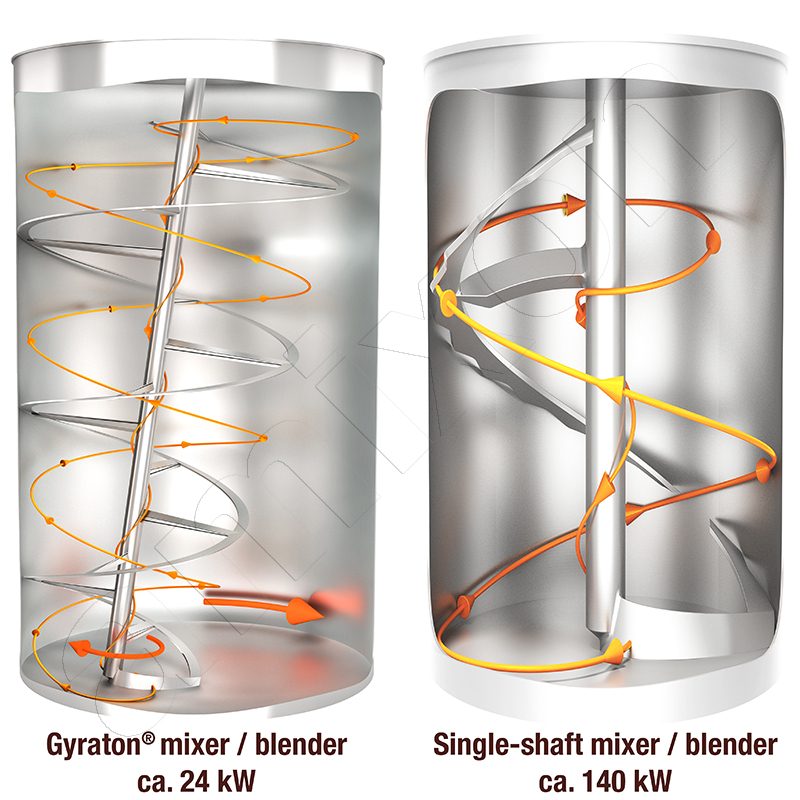

With the Gyraton® silo mixer, amixon® offers an innovative solution for demanding fermentation processes. The helical mixing tool works with a combination of rotational and precessional movements. This results in ideal mixing quality – even at minimum speeds.

The mechanical power input is so low that sensitive microorganisms and cell structures are protected.

The Gyraton® reactor can be fully heated or cooled – for example, via a double jacket, dimple plate, or half-pipe coils. This ensures precise temperature control throughout the entire process chamber. This ensures complete and uniform material conversion.

Its excellent mixing performance has been proven many times over for powdery solids that are particularly difficult to mix. In comparison, high-viscosity large batches are no challenge for the Gyraton®.

The versatility of the Gyraton® silo mixer makes it an ideal fermenter – especially for scalable, bio-based processes in the pharmaceutical, biotech, or food industries.