Wet cleaning

In powder mixers, wet cleaning is often carried out using rotating washing heads. These have eccentrically arranged nozzles. The water pressure is typically between 1.5 and 2.5 bar. The rotation is carried out automatically by the nozzle jet. All directions in the mixing chamber are cyclically treated.

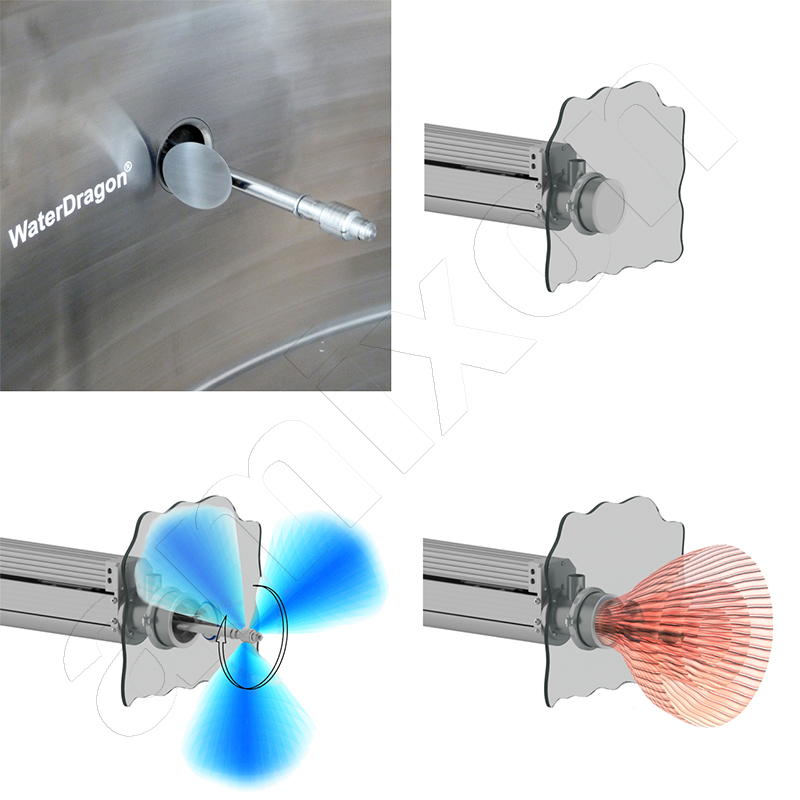

An alternative method is targeted jet cleaning. Here, the nozzles operate at significantly higher pressure. Typical values are between 20 and 80 bar. The directed jet generates high local shear forces. This allows adhesions to be removed very effectively. The cleaning process is thus accelerated. In addition, the overall water consumption can be reduced.

amixon® mixers are equipped with programmable cleaning nozzles. They cover the entire mixing chamber in a targeted manner. Particularly dirty areas are subjected to more intensive cleaning. The cleaning strategy saves time and water. It is reproducible and validatable. This is particularly relevant for applications in the pharmaceutical and food industries.

A cleaning-friendly design is therefore a core element of modern mixers. It must be compatible with industrial robustness. At the same time, mixing quality and process stability must not be compromised. amixon® devices are designed to be particularly easy to clean. Supplementary systems such as WaterDragon® and programmable target jet nozzles enable efficient wet cleaning and drying. This allows for short cleaning times and high process reliability. amixon® is happy to demonstrate all process steps in its technical centre.

Several washing nozzles should be installed in a powder mixer. At least three nozzles are considered appropriate. It is crucial that the mixing tools are also completely covered. These must be cleaned from all sides. After wet cleaning, drying is of central importance. It must be complete and reliable. Residual moisture is critical from a production technology point of view. Effective drying requires smooth surfaces. Dead spaces and undercuts must be avoided. The cleaning medium must be able to drain completely.

-------------

On an abstract level, cleaning performance R can be written as a function of four factors:

R=f(M,T,C,Z)

- M: Mechanics (e.g., abrasive force, shear stress)

- T: Temperature

- C: Chemistry (concentration, pH, surfactants)

- Z: Time (exposure time)

Wet cleaning is normally avoided in bulk solids technology. The reason for this is the high sensitivity of dry production facilities to moisture. This is because residual water can lead to adhesions, microbial risks or subsequent contamination. For this reason, powder mixers are preferably cleaned dry.

Another established method is manual wet cleaning with disposable cloths. This method utilises the adhesive effect of slightly moistened textiles. The surfaces are only lightly moistened, but not flooded. This means that there are no drops or free-flowing water. In this way, dust residues can be reliably removed. The remaining moisture evaporates immediately. The water vapour load on the environment remains low. After cleaning, no measurable residual moisture remains in the mixer. However, this method must be carried out manually. It reaches its limits when it comes to stubborn dirt. It is also sometimes insufficient when high demands are placed on reproducibility.

In such cases, wet cleaning is carried out. This can be done manually or automatically. Wet cleaning has been well researched scientifically. One theory is the so-called ‘Sinner's model’. It was systematised by Henkel AG, among others. It describes the factors that contribute to successful wet cleaning. These include the mechanical effect, the duration of exposure, the temperature and the chemistry. These are supplemented by design aspects and safe drainage. Modern developments also take into account flow control and automation.