Joint-free

OmgaSeal® and sterile flange connections should be used where wet cleaning is carried out regularly. The smooth weld seam is by far the most hygienic seal.

The term ‘joint-free’ is of central importance for the hygienic design of bulk material mixers. Every flange connection or screw connection represents a potential joint. These joints can accumulate residues and are difficult to clean. The aim of modern designs is therefore to avoid joints as far as possible.

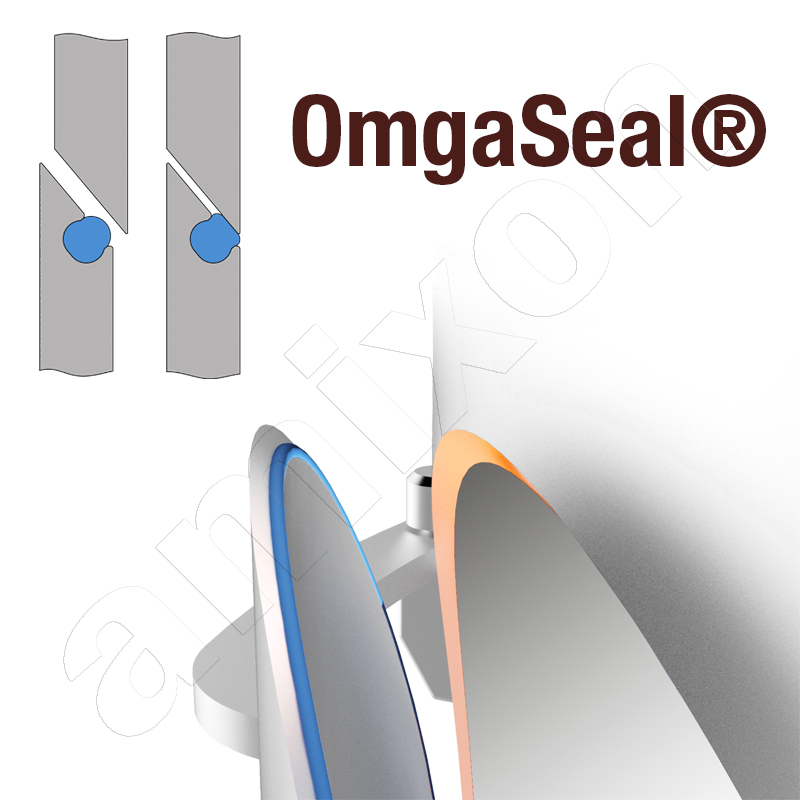

So-called hygiene flanges are an effective means of achieving this. These use O-ring seals that are located in dead space-free grooves. The O-ring is positioned so that it protrudes into the process chamber with a slight curvature. This ensures that the sealing area is optimally aligned with the product. Flange surfaces and seals form a virtually dead space-free unit.

Such ‘hygiene flanges’ comply with EHEDG recommendations. They must be able to be cleaned completely wet. Complete drying is equally important. Water is particularly difficult to remove from narrow gaps or capillaries. Areas that are difficult to dry must be avoided by means of suitable design. It has proven effective to dispense with flanges and weld the mixer completely on the inside. Each weld seam is ground to a bright finish. Weld seams in corners are rounded with a radius R greater than or equal to 6 mm. This process has been used at amixon® for over 40 years.

Inspection doors without joints and without dead space

Equipment must be permanently gas-tight. Nevertheless, simple inspection should be possible at any time, ideally without tools. This means no screw connections that need to be loosened. Modern precision mixers therefore have hygienically designed inspection doors with quick-release fasteners. For safety reasons, these are locked and can only be opened when the mixing tools are at a standstill.

The same hygienic requirements apply to the inspection doors as to the flanges. Sealing is achieved by O-rings arranged without dead space. amixon® mixers use the specially developed OmgaSeal® design. This enables particularly product-tight sealing and a virtually dead space-free design.

A hygienically designed amixon® mixer can be completely wet cleaned and reliably dried. The different cleaning methods: The various cleaning methods – dry cleaning, wet cleaning and wet cleaning with subsequent drying – are demonstrated and validated in mixing tests.