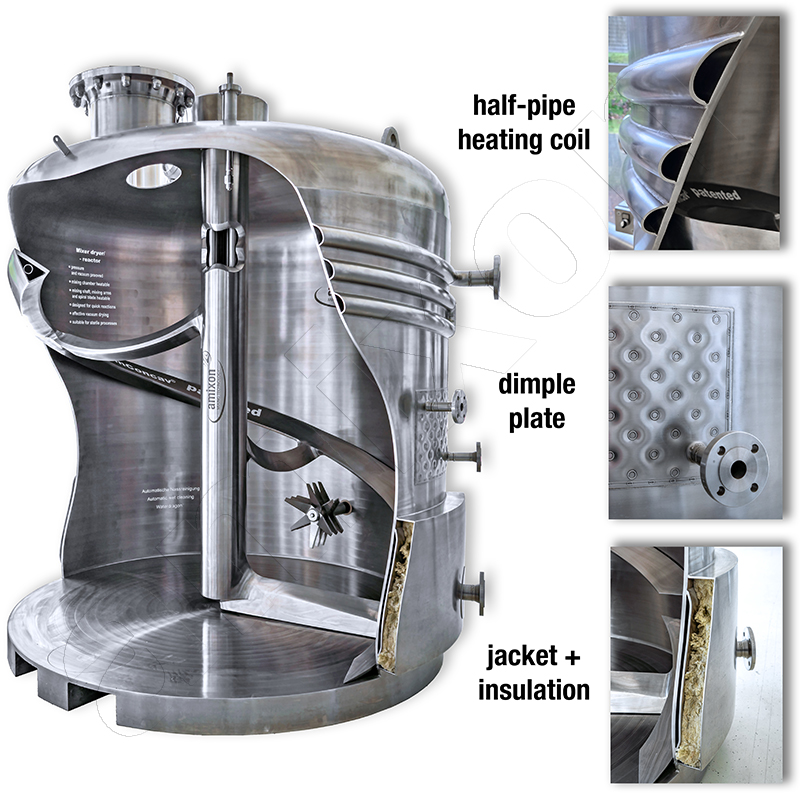

Half-pipe coils

Half-pipe coils are created when a pipe is split lengthwise and the resulting half-pipes are welded to the outer wall of a process apparatus. A thermal fluid can be passed through these half pipes to control the temperature of the process apparatus. Temperature control is used for targeted heat transfer and is standard in many process engineering applications. Half-pipe coils are one possible design for temperature-controlled apparatus.

Another method is the classic double jacket. Here, the process vessel is encased in a slightly larger sheet metal jacket that is welded tightly to the base vessel. A thermal fluid can also circulate in the resulting cavity.

A third design type is the so-called dimple plate. It is based on the double jacket principle, but is additionally provided with holes in a regular grid pattern. At these holes, the outer sheet metal is pressed towards the base vessel and welded. This creates a system of supporting connection points that can withstand high pressures.

Half-pipe coils offer similar advantages to dimple plates. With both designs, the thermal fluid can be at high pressure. The forces generated are reliably transferred to the wall of the base vessel by the large number of weld seams. Half-pipe coils and dimple plates are preferred when the thermal fluid is under high pressure. This is typically the case when hot steam is used.

Classic double jackets, on the other hand, are often used when the temperature control medium is liquid and incompressible, such as thermal oil or water. Nevertheless, a double jacket can also be useful in steam applications, especially if the largest possible heat transfer surface is to be achieved.

As all three types of design are pressure-bearing components, the utmost care must be taken when preparing and carrying out the welding work. After completion, these components are filled with an incompressible test medium such as water or thermal oil and subjected to an increased test pressure. This test pressure is higher than the subsequent operating pressure and is usually 1.3 to 2 times the permissible operating pressure.

amixon® manufactures all types of designs and has domestic and international pressure equipment qualifications.