macro trends

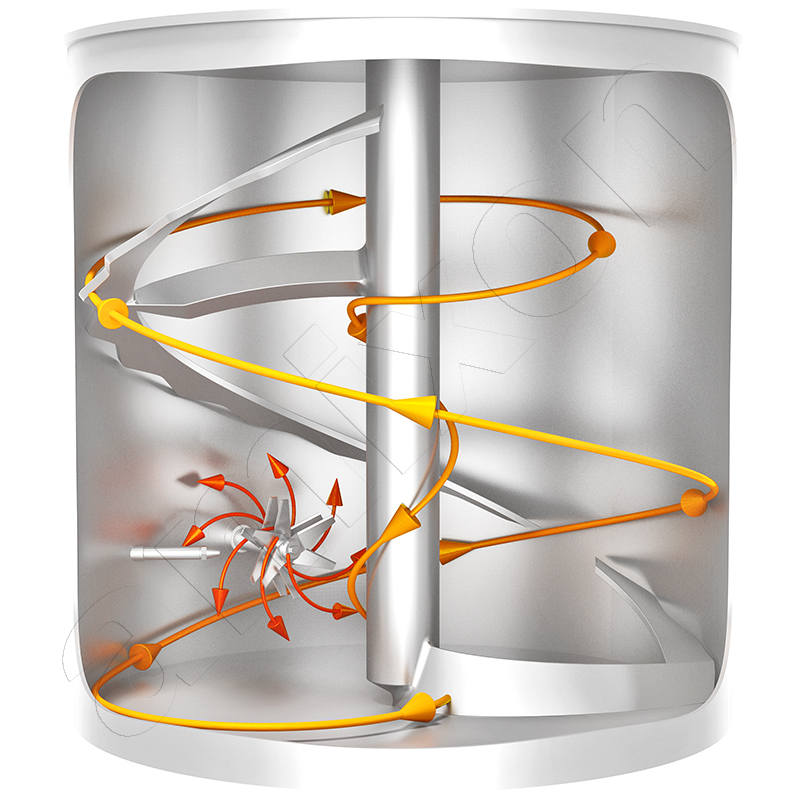

Macro-currents refer to large-scale movements of bulk material in the mixing chamber. In the amixon® mixer, they are created by the spiral-like geometry of the rotating mixing tool in the upright container. The mixing spiral conveys the mixing materials upwards along the wall of the mixing chamber. Once at the top, they flow back down in the centre. This creates a closed circuit that continuously moves the entire volume of the mixture. These macro flows cause rapid and thorough mixing of the entire volume.

Depending on the type of mixing task, high-speed cutting rotors can also be used. These ensure that agglomerates and lumps are broken up. Only when all particles are present as so-called primary particles can an ideal mixing quality be achieved. Agglomerates and lumps are broken up by impact, friction and shearing effects. This intensive mixing process is also referred to as microflow.

The two types of flow complement each other. In amixon® mixers, both types of flow act simultaneously and complement each other. They are optimally coordinated and produce ideal mixing results with minimal energy input.

In practice, this means short mixing times and maximum preservation of the particle structure.

This also results in an important special feature: the mixed goods are hardly heated at all during mixing.