Surface

The term “surface” is of central importance in process engineering. It describes the interface between a solid body and its environment. In mixers, contact dryers, and synthesis reactors, this is the interface between the process apparatus and the product. This interface influences the behavior of the product throughout the entire process.

From a physical point of view, the surface is an area of increased energy. Atoms and molecules on the surface are not completely bound. This results in surface energy, which determines the wetting and adhesion behavior. This energy influences whether a product adheres or flows off easily.

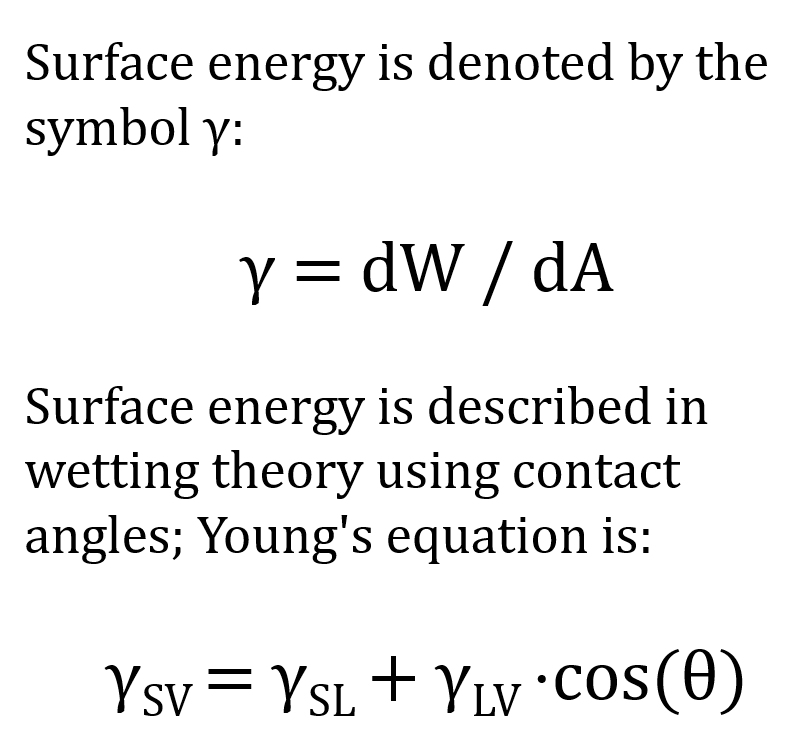

Surface energy is denoted by the symbol γ.

γ = dW / dA

- γ is the surface energy in J/m².

- dW is the reversible work required to create a new surface.

- dA is the newly created surface.

In wetting theory, surface energy is often described in terms of contact angles; Young's equation is:

γSV = γSL + γLV ·cos (θ)

- γSV is the surface energy of the solid-gas interface

- γSL is the interface energy between the solid and the liquid

- γLV is the surface energy of the liquid

- θ is the contact angle

From a chemical point of view, the surface is the site of possible interactions. Adsorption, chemical reactions, or catalytic effects can occur here. For process equipment, it is therefore crucial that the surface is chemically inert. It must neither release components into the product nor promote reactions. For this reason, corrosion-resistant steels and nickel-based materials are preferred. There is a glossary entry on this topic: “Nickel-based materials.”

Components that come into contact with the product include the mixing chamber, mixing tools, seals, and fittings. None of these surfaces may exert any physical or chemical influence on the mixture. In addition to the choice of material, the geometric design also plays an important role. Dead zones, gaps, and undercuts must be avoided in the design. The aim is to ensure complete product discharge at the end of the process.

The surface finish has a direct influence on adhesion and cleanability. Smooth surfaces reduce the actual contact area between the product and the equipment. This reduces adhesive forces and product adhesion. At the same time, the risk of residues and cross-contamination is minimized.

The quality of a surface is described by roughness parameters. In the process industry, the mean roughness Ra is the most commonly used parameter. Typical requirements are Ra less than 0.8 micrometers. For pharmaceutical and hygienically demanding applications, values below 0.4 micrometers are often required. As roughness decreases, the mechanical anchoring of particles in the surface decreases.

Ra is defined as the arithmetic mean of the absolute deviations of the roughness profile.

Ra = (1 / L) · ∫₀ᴸ |z(x)| dx

z(x) is the profile deviation and L is the measurement length. In the process industry, typical requirements are Ra < 0.8 µm. For pharmaceutical and hygienic applications, Ra < 0.4 µm is often required. As roughness decreases, the mechanical anchoring of particles decreases. The effective surface area A_eff of an apparatus is greater than the geometric surface area A_geo. The relationship can be simplified as follows:

Aeff = Ageo · (1 + k)

- Aeff is the effective, real surface area

- Ageo is the ideally smooth, geometric surface area

- k is the roughness factor

The roughness factor k increases with increasing roughness. In addition to mechanical processing, the surface can be electropolished. Electropolishing preferentially removes microscopic roughness peaks. This results in a very homogeneous, smooth, and passive surface. At the same time, chromium accumulates on the surface, which increases corrosion resistance. In individual cases, electropolished surfaces exhibit the opposite cleaning behavior. The cleaning agent can sometimes have difficulty rinsing away the dirt. The reason for this is the smoothness of the surface. Due to their more or less pronounced abrasiveness, the surfaces of solid-state processing equipment that come into contact with the product become increasingly smoother over the course of their service life.

A high-quality surface usually facilitates complete discharge of the product. Product losses are reduced. The cleaning effort is also significantly reduced. Dry, damp, and wet cleaning processes can be carried out more quickly and safely. The consumption of cleaning media is minimized.