Nanofoam

A nanofoam is a dispersed system containing gas phases in the nanometre range. The individual gas bubbles or pores are typically smaller than one micrometre. They often range from a few tens to a few hundred nanometres.

Nanofoams can be produced in various ways. In liquids, nanofoams are often generated by intense energy inputs. These include ultrasound, high-pressure relaxation or special mixing processes. Stabilising surfactants, polymers or particles can prevent the gas bubbles from coalescing too quickly. Due to the small bubble size, the Laplace pressure increases significantly. This distinguishes nanofoams clearly from classic macroscopic foams.

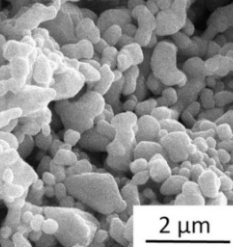

Another possibility is the production of nanofoams from melts. To do this, gas is introduced into a polymer melt or metal melt. This can be done, for example, using physical blowing agents or chemical gas generators. After expansion, the melt solidifies in a controlled manner. This creates a solid foam with closed or partially open nanopores. Such materials have a very large internal surface area and low density.

Nanofoams are used because of their high specific surface area. This promotes mass transport, adsorption and reaction kinetics. Nanofoams can serve as a carrier phase when the liquid is converted into a gas-liquid dispersion with a nanoscale structure. This opens up interesting approaches for powder mixing and powder wetting.

For example, nanofoams can be introduced into powder mixtures instead of liquid. The liquid phase is then extremely finely distributed. This improves the wetting of individual particles. Particularly highly absorbent or hygroscopic powders benefit from this. In addition, local over-wetting and agglomeration can be reduced.

This approach is also relevant for reactive systems. Reactants can be present in foam lamellae or at gas-liquid interfaces. The diffusion paths are short. This allows reactions to proceed in a more homogeneous and controlled manner. This applies to both chemical reactions and physical coating processes.