Ball segment valve

A ball valve consists of a perforated ball. If the bore axis is aligned with the pipe axis, the medium can flow through unimpeded. Turning the ball reduces the flow. If the bore axis is at right angles to the pipe axis, the flow is completely shut off.

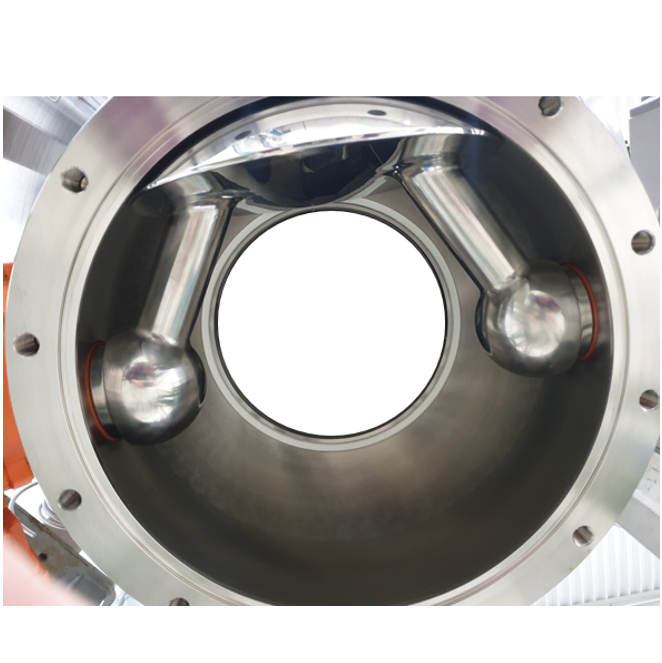

The difference between a ball valve and a ball segment valve is that in a ball segment valve, only the ball cap serves as the closing element. This reduces the weight of the valve and improves cleanability. The lower friction during closing and opening also reduces the switching forces. Some valves have metal seals. Polymer seals can be used for gas-tight sealing. In demanding applications, seals can also be expanded pneumatically to ensure a secure and leak-free seal. This is particularly important when there are pressure differences.

The term ‘valve’ (according to DIN EN 736-1 and DIN 24255 ff.) refers to a component in pipelines or apparatus that specifically blocks, regulates or controls the flow of fluids – i.e. liquids, gases or bulk solids. A valve is therefore an active functional element of a process system. It works via an adjustable closing element that is operated from the outside so that the operator does not come into contact with the medium.

If the media are free-flowing and free of particles, a valve can be of simple design. However, when handling powdery or granular solids, closing or dosing poses a particular challenge. When shut off, particles can enter the sealing gap and become lodged there. Due to the abrasive effect, this can lead to seal wear or leaks.

There is an additional requirement for discharge valves on mixers, vacuum mixing dryers or synthesis reactors: when closed, the valve must seal without dead space. This means that there must be no recesses or niches and the closed valve should be coplanar with the inner contour of the mixing chamber.

Only a few types of valves meet these requirements. Proven solutions include the DosiFlap® from amixon®. They enable safe, dead space-free and easy-to-clean closure while maintaining good dosing capability.