Mixing preparation of baby food

amixon® mixers are frequently used in the production of dietary foods. Trace elements, vitamins, probiotics, polyphenols, flavonoids, carotenoids, collagen peptides, omega fatty acids etc. are added to the powdered nutrient.

The area of responsibility of the baby food manufacturer is large: raw material selection, raw material preparation, dosing, mixing process and filling. All process steps must be optimally harmonised.

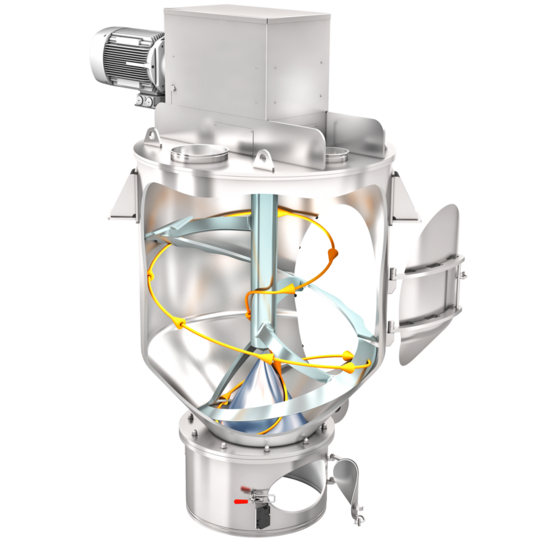

The larger the product portfolio of a baby food manufacturer, the more flexible the manufacturing process needs to be. This applies in particular to complete emptying and cleaning. KoneSlid® mixers have been specially developed for this industry. They mix extremely gently, yet quickly and with ideal accuracy.

Varietal purity of the mixed batches

amixon mixers offer outstanding properties in terms of residual emptying and cleanability. All mixer components are easily accessible and visible.

Any remaining dust is removed with a hoover.

For allergen/non-allergen separation, the mixer can be cleaned fully automatically wet or manually with damp cleaning cloths.

The mixing chamber has two large inspection doors opposite each other. The outlet housing also has two large inspection doors opposite each other. They are manufactured using the OmgaSeal® process and are considered to be exemplary dead space-free.

amixon mixers offer outstanding properties in terms of residual emptying and cleanability. All mixer components are easily accessible and visible.

Any remaining dust is removed with a hoover.

For allergen/non-allergen separation, the mixer can be cleaned fully automatically wet or manually with damp cleaning cloths.

The mixing chamber has two large inspection doors opposite each other. The outlet housing also has two large inspection doors opposite each other. They are manufactured using the OmgaSeal® process and are considered to be exemplary dead space-free.

© Copyright by amixon GmbH