Mixing quality analysis

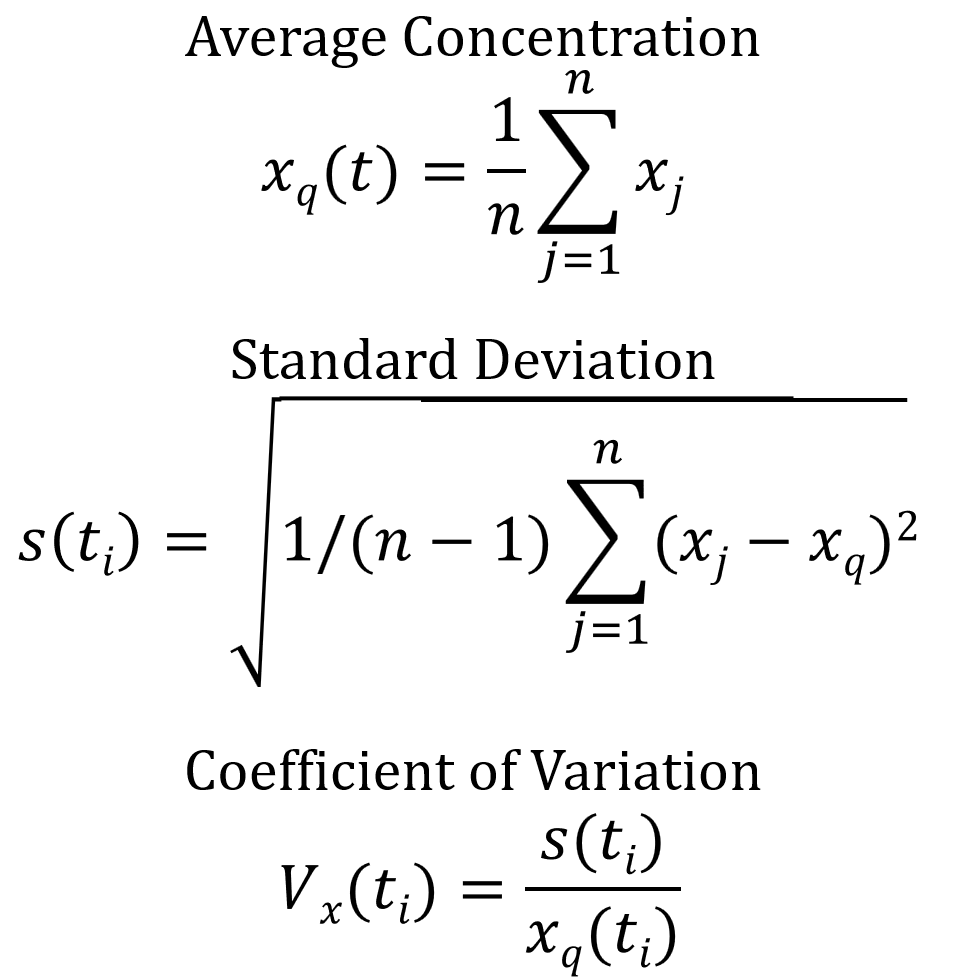

The mixing quality describes how evenly several components are distributed in a mixture. In powder mixing, it encompasses both the spatial distribution of the solid particles and the homogeneity of liquid additives that are added to a bulk material. In practice, the mixing quality is usually assessed on the basis of samples taken from a batch or a continuous product stream. The analysis often focuses on a minor component that serves as a tracer and is evaluated as representative of the homogeneity of the entire mixture.

The basis of any quantitative mixture analysis is the reliable identification of these minor components in the sample. This is particularly challenging when the particles are very finely dispersed or their mass fraction is in the trace range, for example at ratios of 1 : 10,000 or 1 : 100,000.

Optical methods are often used that work with colour contrasts, fluorescence or characteristic spectral signatures. For this purpose, the sample is frequently dispersed in a medium in order to determine the mixture-sensitive component photometrically. The evaluation is then based on Lambert-Beer's law, which links extinction to concentration.

Another approach is to count individual particles of the minor component directly. This can be done using microscopic image analysis, image processing of micrographs or automated particle detection. Granulometric methods based on laser diffraction or image analysis, for example, can also provide information on size and distribution. Depending on the requirements, material-selective methods such as X-ray fluorescence, Raman and infrared spectroscopy, thermal analysis or magnetic and electrical measurement methods may also be used. The suitability of a particular technique depends on the properties of the tracer component, the matrix of the mixture and the required detection limit.

Despite this variety of methods, it is often difficult to establish robust and transferable analysis protocols in industrial solid-state processes. Particularly problematic are finely dispersed, adhesive or surface-active substances that are present in very low concentrations and tend to agglomerate or adhere. In such cases, the mixing quality is often only assessed indirectly in practice, for example on the basis of chemical uniformity, reaction kinetics, particle size development, tablet hardness, dissolution behaviour, colour or gloss distribution, and other functional product properties. For high-performance applications in the fields of chemistry, metallurgy, ceramics and battery materials, the analysis of mixing quality therefore remains a central but methodologically demanding element of process and product development.

Many powdered bulk products are very expensive and require the highest purity and perfect mixing quality in order to be processed economically. These include battery active masses, powder metals, APIs, food additives, thickening agents, construction chemicals, as well as tea, coffee and tobacco.

The longer the downstream process route, the more crucial it is to have ideal initial distribution. This is where the Gyraton® mixing silo comes into play. It has a capacity of up to 100 m³ and has been proven to produce ideal mixing qualities that cannot be improved upon in practice. Its gentle, energy-efficient mixing process with minimal power requirements conserves expensive raw materials and optimises the entire value chain.