Inspection doors

Inspection doors are an indispensable component of process equipment such as powder mixers, vacuum mixer dryers or synthesis reactors. They allow a direct view inside the process chamber and are also used to carry out maintenance and cleaning work.

Inspection doors must have a high degree of rigidity to ensure that they function reliably in process engineering systems, even under negative or positive pressure. This is the only way to ensure that the system remains gas-tight.

Hygienic requirements

Inspection doors present a particular challenge from a hygiene point of view and with regard to mixing without dead space. The products to be mixed should mix completely without powder or particles being deposited in niches or corners. Any dead space would impair the mixing quality and cleanability of the equipment.

Sealing

Gas-tight inspection doors are usually fitted with polymer seals, which can be designed as O-rings or flat seals. The particular challenge in the design lies in the transition between the metallic material and the polymer seal: this area should be as free of dead space as possible or at least minimise dead space in order to meet hygiene requirements.

OmegaSeal® - the solution from amixon®

amixon® has developed an innovative solution for this requirement profile: the OmegaSeal® inspection door. The inspection door is cut out of the casing of the appliance at a constant angle. The door leaf is the moving part of the construction.

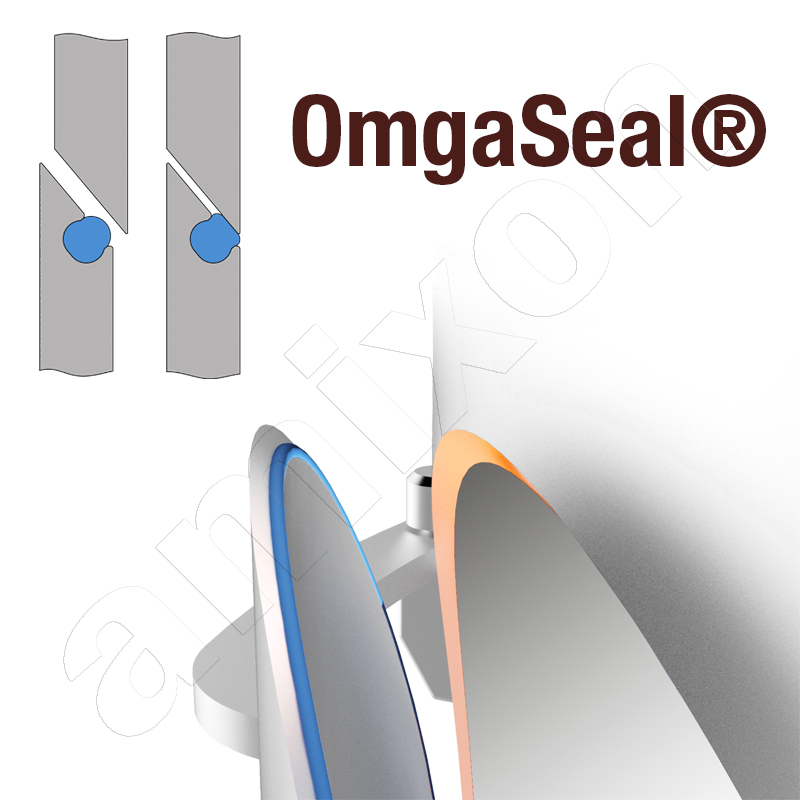

A groove is milled into the face of the appliance wall, which widens slightly towards the bottom. The shape of this groove is reminiscent of a dovetail groove, but is completely rounded. A suitable polymer O-ring is inserted into this rounded groove, which is reliably secured against falling out due to the rear curvature. This shape also gives rise to the name: OmegaSeal® - based on the Greek letter Omega.

Bearing and pressure of the seal

Another crucial design aspect is the bearing of the inspection door in the hinge. The hinge axis must be precisely aligned so that the door moves evenly and without tilting when closing. This ensures that the polymer seal is pressed against the sealing surface in a translational manner, i.e. without rotational movements. Rotational components in the pressure movement would stress the seal and could cause leaks.

Locks and safety interlocks

Suitable locks with safety interlocks are essential for the safe operation of process equipment. The safety interlock prevents operating personnel from opening the inspection door while mixing tools are moving inside. This effectively minimises the risk of accidents while ensuring safe working conditions.

Manufacturing expertise

Our sister company, Clever-Cut GmbH, can manufacture these particularly hygienically designed inspection doors for anyone. Clever-Cut® was founded in 1999 as an independent service company and has extensive experience in the precise manufacture of apparatus components.