Flow aids

Flow aids (also known as anti-caking agents) play a central role in the bulk goods industry. Automated processing and logistics of powders and granulates can only be reliably achieved if the bulk goods flow well. The flow properties influence almost all stages of a production process – from emptying silos, hoppers, IBC containers, big bags and pipes to conveying in pneumatic systems. The precise filling of filling systems, sachet machines or tea bag machines also depends heavily on the flowability of the powders used.

There are a variety of flow aids that are selected specifically for the type of product and industry. These additives improve flowability by preventing clumping, binding moisture or reducing friction. In the food industry, however, inorganic flow aids are usually undesirable. In general, every effort is made to avoid any form of additives that must be declared. The aim is to design the powders intrinsically so that they have good flow properties on their own, especially with regard to their tendency to form bridges or shafts.

If the use of flow aids is unavoidable, the principle ‘as little as possible, as much as necessary’ applies. Typically, the dosage is in the range of 0.04 to 0.1 percent by weight. However, these small quantities pose a technological challenge. This is because flow aids are often very light and tend not to distribute homogeneously in the powder bed – they virtually float. Uniform incorporation therefore requires the highest mixing accuracy.

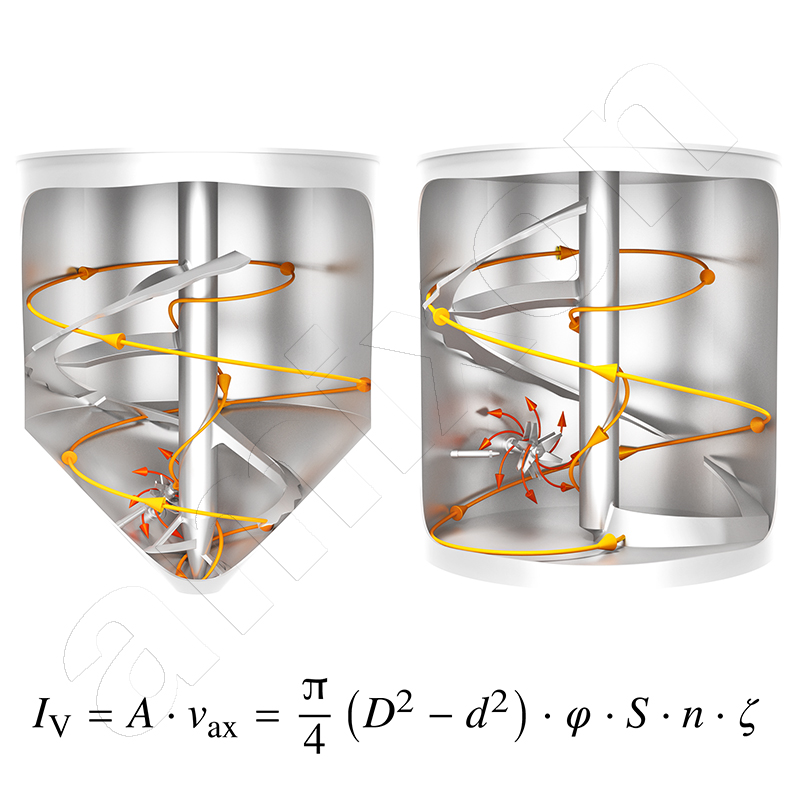

This is where amixon® offers excellent solutions.Our precision mixers are specially designed to distribute even the smallest quantities of additives homogeneously in a short mixing time – with minimal energy input. This demanding balancing act between mixing quality, time and energy efficiency is achieved thanks to our innovative mixing technology. The performance can be demonstrated at any time in our technical centre – in batch sizes tailored to the customer's application.

Some manufacturers and brands of anti-caking agents:

- Cabot Corporation – e.g. Cab-O-Sil®, a highly dispersed silicon dioxide

- Evonik Industries – with AEROSIL®, a pyrogenic silica

- Huber Engineered Materials – including HuberSil®, a precipitated silica

- PQ Corporation – with Silcron® and other silica-based products

- IMCD Group / Brenntag – as a distributor of various brand-name products in the field of functional additives.

Flow aids are more than just technical additives – they are often essential for a smooth and economical production process. The right choice and optimal incorporation into the product are crucial. This is exactly what amixon® technology stands for.