Nanoporous material

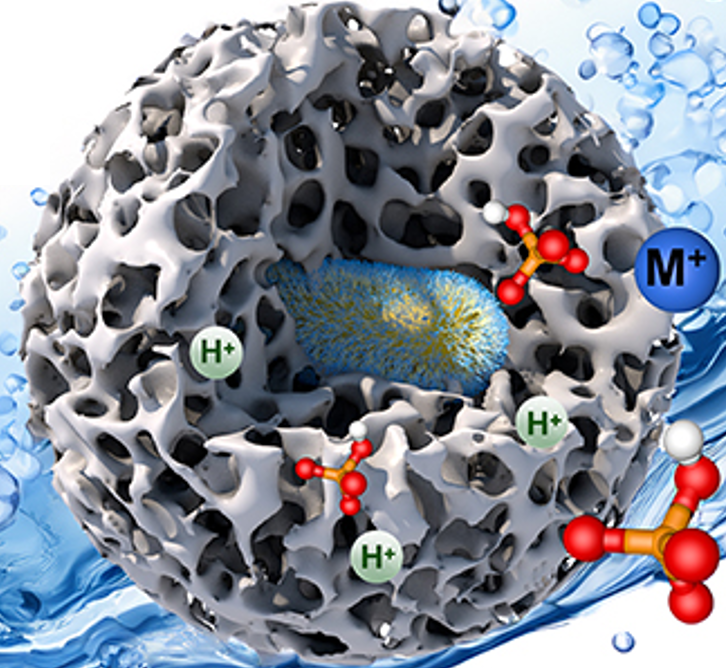

Nanoporous materials are solids with a pore system in the nanometre range. The pores can be open or closed. Typical pore diameters are less than 50 nm. Nanoporous materials have a very large internal surface area. This can reach several hundred square metres per gram.

The large specific surface area results in high adsorption capacity and reactivity. Nanoporous materials are used in high-performance applications in chemistry, energy technology, electrical engineering and engineering ceramics. Typical examples are catalysts, adsorbents, electrode materials and functional composites.

The production and processing of nanoporous materials is technically demanding. The pore structure is often created from nanoscale primary particles or through the use of templates. The homogeneity of the initial mixture directly influences the subsequent pore distribution and functionality.

Nanoporous powders are mechanically sensitive. High shear or impact loads can lead to the collapse of the pore system. At the same time, controlled deagglomeration is necessary to ensure uniform distribution. The mixing process must therefore be carried out with great precision.

Many nanoporous materials are present as secondary agglomerates. These can restrict the accessibility of the inner surface. The aim of mixing technology is to gently open the agglomerates without destroying the pore structure.

Gentle mixing processes are particularly suitable for this purpose. The amixon® mixing process enables homogeneous mixing with low mechanical stress. Sensitive hollow particles and nanoporous structures can thus be effectively protected.

Nanoporous materials play a key role in the development of modern high-performance materials. Their properties are determined not only by their chemical composition, but also significantly by the mixing process control.