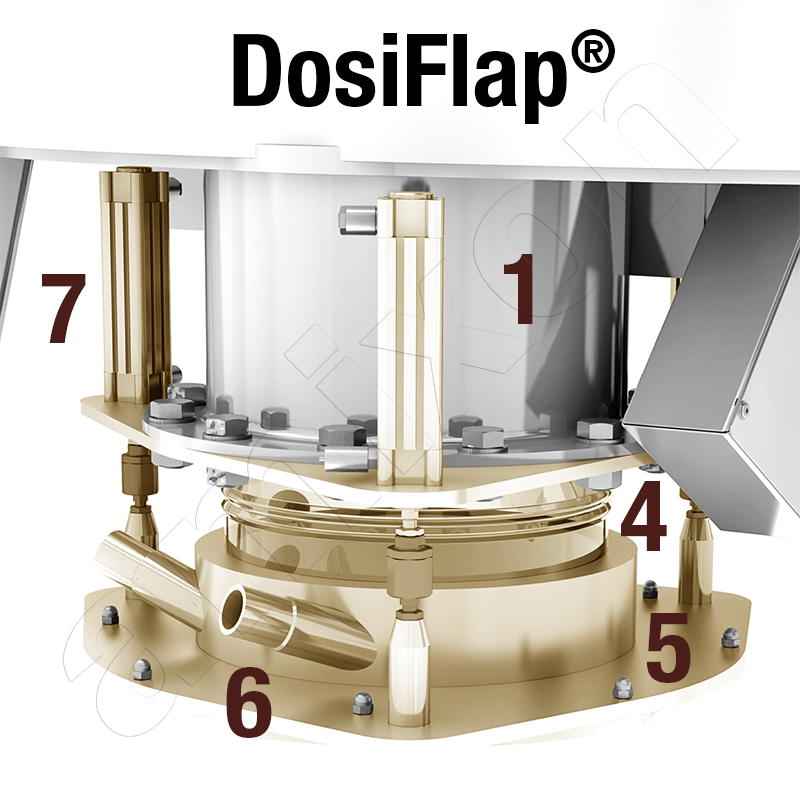

DosiFlap

DosiFlap® is a registered trademark of amixon® and refers to a dead space-free shut-off valve that is installed as a dosing and shut-off unit below powder mixers. Unlike conventional bottom flaps, DosiFlap enables gas-tight and process-reliable shut-off of the product flow even when powder is still being discharged (batch discharge).

Technical background

In powder mixing technology, it is common practice to integrate closure flaps flush with the floor into the mixing chamber. This prevents deposits and dead spaces that could impair mixing quality or product hygiene. Conventional closures are usually designed as swing flaps that sit inside a standard socket and are operated pneumatically or mechanically from the outside.

However, such flaps may only be closed when the mixer is empty. Closing them during the emptying process can cause powder residues to become stuck in the seal, damaging the sealing surface and preventing complete closure.

The DosiFlap® system has been specially developed to enable reliable and hygienic sealing even during product discharge. It allows dead space-free mixing right up to the discharge area. The vertical space requirement is low. DosiFlap® can be closed at any time and the system remains completely gas-tight even when closed.

The system is particularly suitable for

- For processes involving: frequent product changes,

- for high hygiene requirements (e.g. food, pharmaceuticals),

- for poorly flowing or

- for sensitive powders.