mixing effect

In powder mixing, the mixing effect is the ability to rearrange the powder particles so that they are distributed homogeneously in the powder mixture. A high mixing effect is achieved when all areas of the batch are regularly and completely permeated.

Mixing is based on the physical principle of diffusion. While diffusion occurs quickly in gases, it is significantly slower in liquids and only possible to a negligible extent in solids. The driving force is concentration equilibrium, in which molecules migrate randomly to achieve a more energetically favourable state of homogeneous distribution.

Molecular diffusion plays hardly any practical role in the mixing of solids. Industrial mixing processes mainly achieve homogeneity through relative movements between particles. These occur when bulk materials are set in motion. Depending on the process, the flow is caused by gravity, forced movement or rearrangement, for example in free-fall mixers, horizontal or vertical forced mixers, mixing silos or mixing piles.

The mixing effect describes the effectiveness of these particle rearrangements in terms of their ability to produce a random and uniform distribution of all components. A high mixing effect is achieved when all areas of the batch are regularly and completely flowed through, dead zones are avoided, and the particles are statistically well distributed through the superposition of various flow mechanisms such as convection, dispersion, and particulate diffusion.

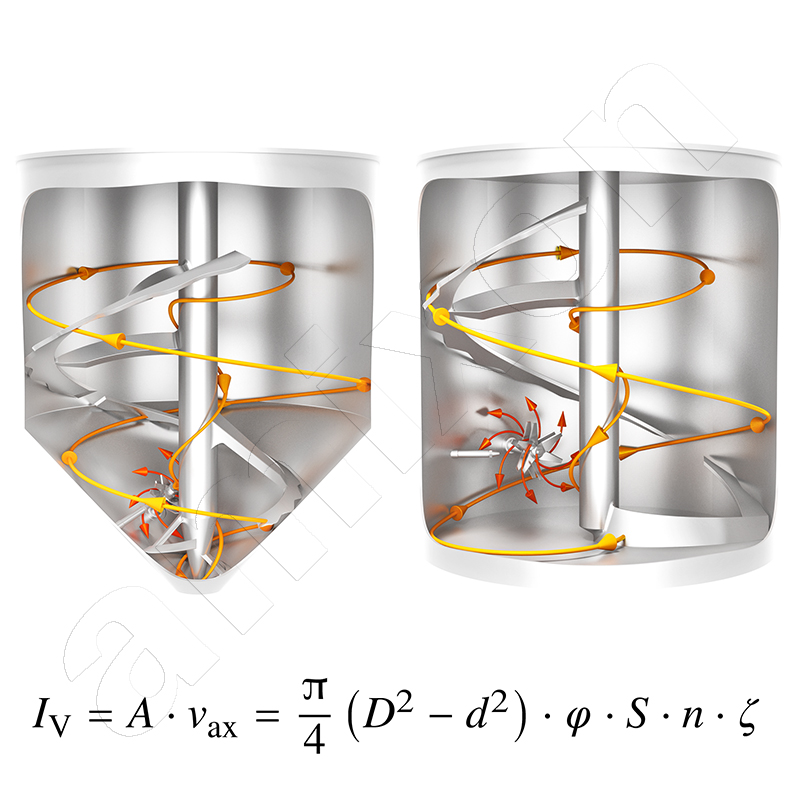

With vertical mixers from amixon®, the extent of particle repositioning can be quantified with a high degree of accuracy. For this purpose, the conveying capacity is estimated using the screw conveyor formula established for steep screws. This characteristic value serves as an indicator of mixing efficiency. Since the resulting flow process is largely free of dead space, ideal mixing quality is achieved in a short time and with very low specific energy input.

Q = (π · D2 / 4) · S · n · φ · ζ

Q … theoretical output

D … screw diameter

S … Pitch of the screw

n … Rotational frequency of the screw

φ … Filling level of the worm gear (normally 100%)

π … pi

ζ … Correction factor/efficiency of support

The mixing effect can be enhanced by additional measures:

- Increase in the conveying speed of particle movements

- increase the rotational speed of the screw conveyor,

- optimise the gap between the pipe and the screw

- optimise the screw pitch

- Installation of "flow disruptors"

- ……

The mixing effect can be further improved by using dry or liquid mixing accelerators. These increase the energy density locally in the boundary areas of the particles or alter the interactions between them.