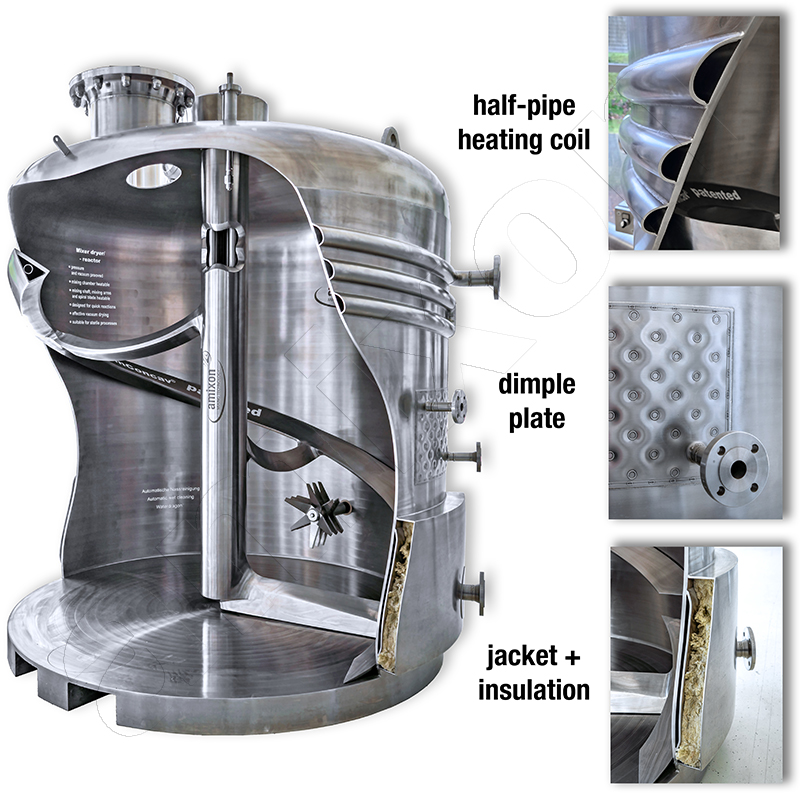

Double jacket

A double jacket is a closed cavity that is used to control the temperature of process equipment. It completely or partially encloses the process vessel and a heat transfer fluid (e.g. steam, water, thermal oil) flows through it in order to heat or cool the product in a targeted manner.

Typical designs are

-

welded shell casings,

-

Half-pipe snakes (half-pipe heating coils),

-

structured heat transfer plates (dimple plates).

Double-walled amixon® appliances are characterised by particularly uniform and rapid heating of the entire mixing chamber. This means that the mix is heated quickly and without localised temperature differences. Cool zones in which unwanted condensation can form are reliably avoided. This is particularly advantageous for synthesis reactions and vacuum mix drying processes.

The thermal efficiency depends on the mass flow of the heat transfer medium, a small temperature delta between the inlet and outlet and a low pressure loss.

A double jacket is also used in flow-through coolers or condensers, among other things.