Wetting

Wetting is the physical process in which a liquid comes into contact with a solid surface and spreads across it. An interface is created at the boundary between the liquid and the solid, and its energetic properties determine the wetting behavior. In this context, powder moistening describes the penetration and distribution of a liquid in a powdery, porous particle aggregate.

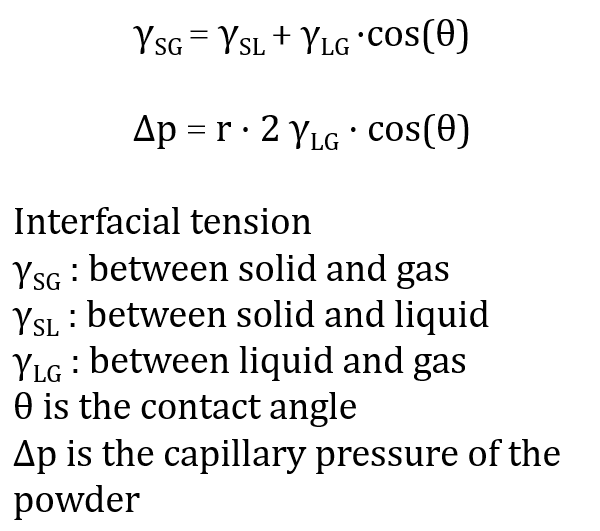

The wetting behavior is influenced by the interfacial tensions between the solid, liquid, and gas phases. A key measure is the contact angle, which is described by Young's equation:

γSG = γSL + γLG ⋅cos(θ)

γ_SG is the interfacial tension between the solid and the gas, γ_SL between the solid and the liquid, and γ_LG between the liquid and the gas. θ is the contact angle. Small contact angles indicate good wetting; large contact angles indicate hydrophobic surfaces. In porous powder aggregates, capillary pressure also plays a role, which can be described by Laplace's equation:

Δp = r ⋅ 2 γLG ⋅ cos(θ)

r represents the effective pore or capillary radius. Fine powders with small pores and a hydrophilic surface quickly absorb liquids due to strong capillary suction forces. Hydrophobic or coarse-pored systems require higher pressures or more intensive mixing to distribute the liquid evenly.

The distribution of liquid in the powder typically takes place in two steps. First, a liquid film forms on the outer particle surfaces, then the liquid penetrates into the interior of the aggregate. The speed and uniformity of moistening depend heavily on the drop size, drop impact energy, viscosity, and surface tension of the liquid, as well as the particle morphology. Different wetting properties of the components can promote or inhibit agglomeration, thereby significantly influencing the product structure.

amixon® mixers enable various processes for targeted powder moistening. Liquids can be introduced via single- or dual-material nozzles. The drop size and impact velocity can be adjusted to achieve either fine distribution or targeted initialization of agglomerations. Alternatively, the liquid can be applied as a compact jet from above onto the mixing bed, which is particularly advantageous for viscous or foam-sensitive liquids. Another option is steam injection, in which condensing steam creates uniform liquid films on the particles.

In some cases, it makes sense to evacuate the mixture before adding the liquid. Removing the gas phase deaerates the pore spaces of the particle aggregate. When the liquid is then added, it can penetrate the aggregate more quickly and deeply due to the resulting pressure gradient. This process makes optimum use of the natural porosity of the powder and improves liquid absorption, especially in the case of fine, hydrophilic powders or formulations that are designed to absorb high liquid contents homogeneously.