Powder mixers

amixon® customizes industrial powder mixer machines for diverse processing needs

Powder mixing equipment plays a crucial role across many industries that involve bulk solids processing. From pharmaceuticals to chemical processing to the food industry, there are countless applications for high-performance powder mixing.

Furthermore, powder mixing equipment is itself endlessly diverse. Industrial mixing systems come in all shapes and sizes and perform any number of different powder blending techniques and mixing processes.

Given the tremendous variation in dry ingredients and industry standards, selecting the best powder blending machine for your application requires consultation with experts.

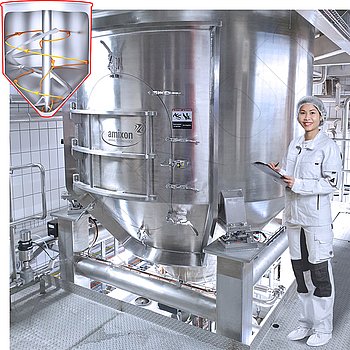

For over 40 years, amixon® has been creating, testing, and customizing powder mixers for market leaders in manufacturing industries worldwide. Between meeting demanding hygienic requirements, to ensuring consistent product quality, to achieving high production output, amixon® builds custom solutions to industrial powder mixing challenges of all kinds.

More than just mixing and blending powders

Not all industrial powder mixers are created equal. Fine-tuned over many decades onsite in Paderborn, Germany, the technology behind amixon® powder blenders and mixing machines offers considerable advantages for your product and manufacturing efficiency:

- Proprietary technology for ideal dispersal and powder flow

- Maximum blend uniformity in short mixing times

- Time-saving, hygienic designs for easy CIP

- Up to 99.997% discharge with diminished segregation

- Adjustable settings, from intensive deagglomerating to gentle homogenizing

- Collaborative product development at six global testing centers

Ribbon mixer or paddle mixer? Inline mixer or cone mixer? From your raw ingredients to your manufacturing facilities, from hygienic regulations to the required mixing precision, many factors must be taken in account when choosing the appropriate powder mixing techniques and equipment. Here are some key factors to evaluate when selecting a powder mixer or blender:

Powder characteristics – How to mix powders evenly ultimately depends on the powders you need to mix. Is the powder sticky or free-flowing? Are the particles superfine or coarse? Do ingredients of varying particle sizes and textures need to be mixed together? amixon® engineers can advise you on the best powder mixing techniques for your application, and the best equipment for the job.

Continuous or batch production – Does your production process operate continuously or in batches? The advantages and disadvantages of continuous mixers vs. batch mixers depends on your product, facilities, and desired output.

Batch sizes – The volume of powders to be mixed can affect loading and discharge times, mixing techniques, change overs, and mixing time among other things. Our high-efficiency powder mixers can be constructed at a wide range of proportions for varying batch sizes and filling levels. From a small dry powder mixer to a thousand-liter tank, amixon® can engineer precisely the powder blending machine you need.

Processing needs – From agglomerating to dispersing, vacuum drying to moistening, the gentle homogenization of fragile ingredients to the high-speed deagglomeration of granular materials, different amixon® mixing systems perform different powder mixing techniques to help you achieve the desired mixing results and batch precision.

Cleaning and hygiene – Is cross contamination a concern for your product? Will the powder mixer need to be cleaned between batches? amixon® powder mixers are built with food-grade materials like stainless steel and grant full access to the mixing chamber and agitator shaft, making for especially easy CIP and fast drying.

Factory specifications – Your ideal powder mixing machine must be a perfect match for the space and resources available within your production facilities. amixon® mixing experts can advise you as to how our powder blending equipment will integrate with your upstream and downstream processes.

Where are powder mixing machines used?

Many of the products we interact with on a day-to-day basis were created in part by bulk solids processing. amixon® powder mixers can be found all over the world. Our industrial powder mixing equipment is used to make everything from food to plastics, make-up to animal feed, medicine to insecticides.

Nutrient mixer/ blender

From processing raw materials to prepping mixtures for packaging, amixon® industrial powder mixers can boost performance and profitability at many junctures in the food manufacturing process.

Used to create baking mixes, cereals, spices, instant foods, and more, our ribbon blenders, agglomerators, and vacuum dryers adhere to the highest food safety and sanitation standards.

Dry ingredients mixed in amixon® machines are:

- dust-free and easy to pack

- free flowing and low in adhesion

- unaffected by heat from the mixing action, retaining their full taste profile

- evenly coated with high-viscosity fatty or liquid additives through high-speed dispersers

- retain desired particle sizes, shapes, and consistencies

Pharmaceutical powder mixers

Evenly blending exact amounts of powdered active ingredient with excipients is not without its difficulties. Achieving and documenting batch uniformity is among the most significant ongoing challenges facing the pharmaceutical industry.

amixon® powder mixing technology optimizes the blending process for consistent results that can dramatically reduce the time and resources spent testing. amixon®has decades of experience building industrial mixers used to bring safe and effective medicines and supplements to patients around the world.

Highlights of our pharmaceutical powder mixing machines include:

- Blend uniformity – Powder blends consisting of highly-concentrated active ingredients and excipients such as starch and cellulose are gently and thoroughly homogenized.

- Tablet coating – Powdery active ingredients can be coated to accelerate or inhibit solubility or oxidization.

- Grain enlargement – Powdery particles can be agglomerated to diminish segregation, boost solubility, and enhance handling characteristics.

Detergent, plastic, and more!

amixon® powder mixing equipment also offers state-of-the-art technology and processing solutions for:

- Cosmetics manufacturers

- Livestock feed and pet food

- Nutritional supplements, protein powders and vitamins

- Household cleaning agents and detergents

- Fertilizers and insecticides

- Powder metallurgy and fine ceramics

- 3D printing

- Plastic granules and pigments

- Powdered emulsifiers